Last Updated on October 22, 2022 by Jordi Hilpert

3D printing was once a costly craft that could cost several hundred dollars to start. Why buy a 3d printer it was difficult to get into the printing industry due to the high costs of printing materials and less user-friendly printers. It’s brighter today, with the average person being able to print great things for $300.

The technology behind this process was first popularized by computer scientists who saw the industrial applications for 3D printing since it could be used for developing custom-made parts through computer design software.

Why buy a 3d printer?

This article will discuss the top reasons to buy a 3D Printer. You don’t have to buy a 3D printer if you already have one. I guarantee you will be surprised by some of the things you learn!

1. Great hobby to learn

Many people have spare time but don’t have hobbies to fill it. 3D printing is a great way to help. 3D printing enthusiasts are a community that uses their time to make a great thing and start projects that can be very useful or for fun. No matter what your motivation, 3D printing will help you discover a lot about yourself and your technical skills.

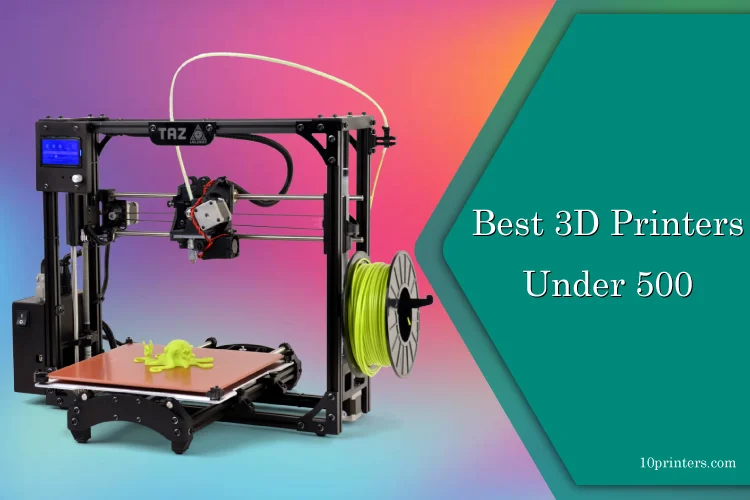

If you want to make your 3D printing experience worthwhile, you should learn how to program it. Although it may seem overwhelming at first, the programs available today are easy to learn and fun. A 3D printer should have the right balance of price, performance, and durability. A lot of 3D printers priced between $150 and $250 are affordable enough to get you started. If you want to buy then visit Best 3D Printers Under 500 Dollars.

However, if your 3D printer is to be premium from the beginning and last a long time, you might consider spending more on a 3D printer that offers great performance, warranty, and features for the intended purpose.

Once you have gained some experience, you will be able to identify the key differences between what you can and cannot 3D print. This is the time I recommend that you spend more money to get more quality 3D printing products.

2. 3D printing gives you a competitive edge

It was a huge change in the manufacturing process of hearing aids, as a result. In a short time, the entire industry was able to change its manufacturing process to include 3D printing.

The majority of companies that adopt additive manufacturing processes of 3D printing report having a competitive advantage. Forbes reports that 95% of companies that used this technology in 2019 achieved this. This is due to shorter lead times, greater adaptability, and a faster production cycle.

This technology not only gives companies an advantage but also allows them to improve their product quality and customer service. Model building can be done in a matter of hours or less due to the speed of innovation.

3D printing can significantly lower the cost of production. For complex yet durable products, 3D printing allows for real customization and design freedom. 3D printing can be very cost-effective for many reasons. One of these is the lower labor costs. The 3D printer does most of the work.

After the design has been created and the settings have been input, 3D printers take over most of the work. This allows for labor costs to be almost eliminated in the manufacturing process.

3. Increase Your Creativity

There is a lot of creativity involved in 3D printing if you’re thinking about it. To create your designs, I recommend that you learn how to use the free Computer Aided Design programs (CAD).

It is possible to transform ideas into designs and then create a 3D printed object. This makes a huge difference in the possibilities of 3D printing.

3D printing is not possible if you don’t have your designs. You can only print what others design.

Although there are many designs available on the internet, Makerbot has a lot more than you could ever imagine. However, it can get repetitive.

This is a cool feature: once you have mastered CAD, you can share your designs with other people to allow them to print. You also get praise and feedback from other users about your creativity. Although there is some learning involved in creating designs using CAD programs, the long-term benefits of 3D printing will outweigh any inconvenience.

This is not all. CAD can be used for many other purposes beyond 3D printing.

4. Makes things for other hobbies

3D printing can be used in many other industries and hobbies. Engineers, woodworkers, and other technical people have used 3D printing in their fields to create a variety of useful items.

Marius Hornberger’s video shows the many real-world applications of 3D printing for him and his space. This guy is an expert, so don’t expect him to be able to do the same thing at this stage. But it’s something you can work towards.

5. Once you get the hang of it, it’s really fun

I have seen people make custom chess pieces and miniatures for Jungle animals and creative characters like Dragons. They also create their games and 3D print sweet collections. Once you’ve mastered the basics, this hobby can be very rewarding and fun.

Sometimes you don’t even need to learn. If you have a reliable printer and know how to set up your settings correctly, your prints will come out exactly as you envisioned. They should also have a sturdy, smooth finish.

Not only can your 3D prints be beautiful, but they also have the potential to serve as functional objects that will aid you in your daily activities. It’s a great way to get your friends and family involved in designing the product. It’s a great way for people to come together in a practical and fun activity.

3D printers are becoming more popular in schools, universities, and libraries. You can do so many things with them. People have printed survival tips that can go over 100 decibels, happy birthday cake toppers, tap sprinkler attachments, and smartphone stands.

6. DIY Solutions for Household Problems

This is related to the previous point about creativity and being practical with your situations. One example comes from a 3D printer hobbyist who lost his dishwasher and could not repair it. Due to the discontinued model, he couldn’t obtain a crucial part from the manufacturer.

He had a lot of experience in designing and was eager to find the right solution. He was given the opportunity to design the part using a free CAD program and then print it.

This is not as easy as it looks. He had to tweak and improve the design several times, but the result was a dishwasher part that was better than the original.

He not only proved his persistence and ability to complete the task, but he also earned bragging rights from his wife! The best part is that if the part ever breaks again, he can have the original design saved so that he can just print another one without any additional design work.

This situation would have been better if the 3D printer and filament were purchased instead of a new dishwasher. He could have started 3D printing before this problem occurred, but there would be a learning curve to gain the necessary experience. It was already a hobby for him so he could jump right into the job.

7. 3D printing gifts for children/people

A few 3D-printed objects have probably been seen, including figurines, action figures, and small toys. These objects make great gifts for cosplay and comic fans, anime lovers, and all children. It is a joy to be able to print your favorite heroes and marvel characters in a variety of colors. There are many options.

This can be a great gift for someone else or a list of birthday/Christmas gifts. Gifts these days tend to be very generic and predictable. However, with a 3D printer, your imagination, and a little bit of creativity, you can get ahead of the gift-giving curve.

8. Earn money with this

Many 3D printer enthusiasts have turned their hobby into a lucrative business. It’s becoming easier to find people willing to pay for specific objects in today’s digital age. There are 3D printing companies out there. But, you can still tap into this market or create your own.

You can make money if you have a niche that is highly sought after, such as children’s toys or board games. If you’re committed to this goal, you could start a social media following or create your website.

Nerf guns, luxury vases, and luxury vases are two examples of ideas people have tried. They seem to be very successful. Training people to 3D print can make you money. Many people are starting to see the benefits of 3D printing, and they want to be able to master the art.

You could provide training or create 3D printing courses for the increasing number of people interested.

It is highly sought-after to be able to design and produce objects according to customer specifications. People will pay you to do this. It can be a great side business for many years if you get good at it.

9. Help your children become technical

3D printing, even though it is still in its infancy, has many benefits for education, particularly for younger students. Many educational institutions, including, universities, schools, colleges, and medical colleges, have introduced 3D printing in a variety of creative ways. 3D printing offers many learning opportunities, including the ability to see 3D-printed designs come to life.

Children have the unique opportunity to interact with finished products and show others what they’ve done.

Everybody knows that children are more excited when they can do practical things. 3D printing does exactly this. It can create bored students who are far away from their usual reading habits and make an interest between practical study and education. Although 3D printing can be difficult to master, once you have it down you will be able to think critically and solve problems better.

This activity sharpens your brain and creativity. The ability to 3D-print complex shapes and sizes can lead to innovation. There are endless possibilities for students.

People retain information better when they have hands-on experience than just reading or listening. Students not only get practical experience but retain information at a higher rate than the average student.

Many universities now offer 3D printing facilities for students. This technology will be adopted by more universities and other organizations in the future. Give your children the chance to get involved early on and rise to the top of their class.

10. Be a part of a growing industry

3D printing is gaining momentum at an alarming rate and the technology behind is improving every day. There have been some advances in printing prosthetics and prototypes, houses, as well as 3D printers (although they are not yet fully developed).

Although it is still in its early stages, once more people see the potential of 3D printing, I can envision a global snowball effect. As 3D printing allows people to create their products and equipment, it is a boon for low-income countries in Africa and Eastern Europe.

It is easy to transport a 3D printer to a place and then print out objects. This saves a lot of money, especially for places that are difficult to reach.

The numbers speak for themselves. The 3D printing sector has seen steady growth in the 15% to 15% range, and even more in lower-income areas. Imagine 10 years from now how far 3D printing can go. Don’t let anyone get in your way!

3D printing has seen an explosion in popularity over the past 3 years. Now printers are affordable and easy to use for beginners. This used to be an area that only the most technically skilled people could use, but times have changed.

11. 3D printing can be environmentally friendly

Science Direct claims that if we adopt additive manufacturing technology (3D printing) globally, global energy consumption could be reduced by 27% by 2050.

3D printing is a more efficient way to produce products than traditional manufacturing methods. This is because the material is added to the product rather than being removed from the larger object.

Traditional manufacturing tends to be more adept at manufacturing larger objects and large volumes, while additive manufacturing can handle smaller, more intricate parts.

Many times, additive manufacturing will not be possible to meet production demand as there is insufficient supply.

It’s a benefit for the environment to have additive manufacturing. This printing method reduces waste and uses only the material that will be used in the final product. These printers consume a relatively small amount of electricity compared to traditional manufacturing methods. In fact, there are many ways to earn money from 3d Printer Waste. Visit what to do with 3d printer waste and scraps?

Manufacturing is a lengthy process. From material extraction to assembly to actual manufacturing, it can leave a significant carbon footprint.

3D printing does not require the many steps required to make a final product. It requires only minimal assembly and refining. We can also reduce transportation, storage, logistics, and many other factors.

This is what gives additive manufacturing and 3D printing the relative advantage in terms of environmental impact. One negative aspect of 3D printing is its widespread use of plastic. This unfortunately creates its carbon footprint during material extraction.

This is a good thing because 3D printers can use many materials. If you don’t want to, you won’t be tempted to use them.

Amazingly, 75% of 3D-printed companies increased their investment in 2019 compared to 50% in 2016.

Conclusion:

If you intend to print a lot of prototypes for your project, a 3D printer will be worth it. If you are just starting to learn 3D modeling or if you only have a few prototypes to print, it is a good idea to hire a 3D printing company.

Although 3D printers can be expensive, especially the more advanced models, the investment is well worth it if the printer is used to its full potential.